En la industria de la electrónica automotriz, calidad y fiabilidad son fundamentales para la seguridad, el rendimiento y la durabilidad a largo plazo. Fabricantes y proveedores de componentes esenciales como MLCC automotrices (Condensadores cerámicos multicapa)Los condensadores de tantalio y los supercondensadores deben cumplir con rigurosas normas internacionales. Entre las más reconocidas se encuentran la IATF 16949 y la AEC-Q, que definen cómo se fabrican los productos y cómo se certifican para su uso en vehículos.

¿Qué es IATF 16949?

IATF 16949 Es una norma global para sistemas de gestión de calidad automotriz, desarrollada por el Grupo de Trabajo Internacional sobre Automoción (IATF) en colaboración con ISO. Combina los requisitos generales de la ISO 9001 con medidas de calidad adicionales específicas para la industria automotriz.

Para proveedores de componentes electrónicos de grado automotriz, desde MLCC automotrices en las unidades de control del motor a condensadores de tantalio En sistemas de infoentretenimiento, la certificación IATF 16949 demuestra la capacidad constante para satisfacer los requisitos del cliente, prevenir defectos y minimizar las variaciones de fabricación. Garantiza que los procesos de producción de condensadores y otros componentes sean controlados, eficientes y fiables.

¿Qué es AEC-Q?

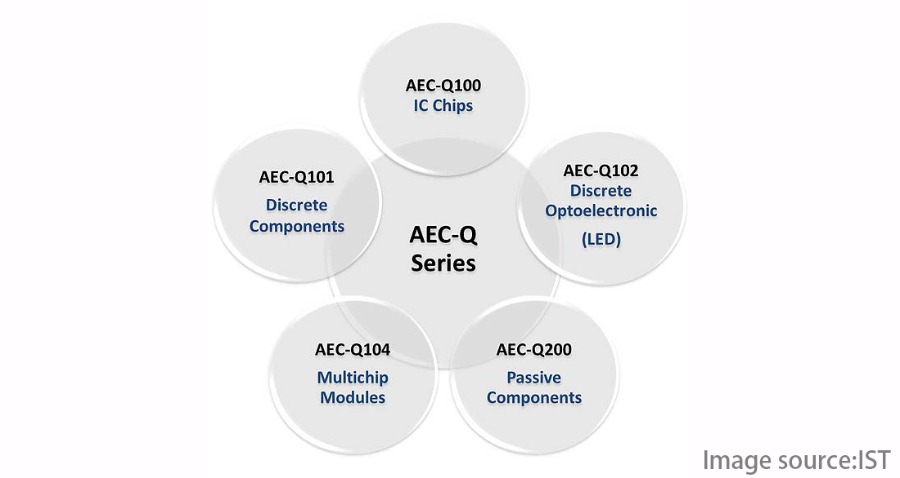

AEC-Q Las normas, creadas por el Consejo de Electrónica Automotriz (AEC), definen los requisitos de las pruebas de fiabilidad para los componentes electrónicos automotrices. A diferencia de la IATF 16949, que se centra en los procesos de fabricación, la AEC-Q se centra en la cualificación a nivel de componente.

Por ejemplo:

AEC-Q200 Se aplica a componentes pasivos como los de automoción. MLCC, condensadores de tantalio, y supercondensadores, verificando su capacidad para soportar ciclos de temperatura, humedad, vibraciones y estrés eléctrico.

AEC-Q100 Se aplica a los semiconductores, garantizando que funcionen de manera confiable en entornos automotrices exigentes.

Cuando un componente cumple con los requisitos AEC-Q, ha sido probado para soportar las duras realidades del entorno automotriz, desde temperaturas extremas en el compartimiento del motor hasta las altas cargas eléctricas en el sistema de propulsión de un vehículo eléctrico.

La diferencia entre IATF 16949 y AEC-Q

Si bien ambos son fundamentales para la cadena de suministro de electrónica automotriz, cumplen diferentes propósitos:

IATF 16949 Es una certificación basada en procesos que garantiza que una empresa puede fabricar constantemente condensadores y otros componentes de alta calidad.

AEC-Q es una calificación a nivel de producto que garantiza que esos condensadores y componentes puedan sobrevivir a las condiciones automotrices del mundo real.

En términos simples, IATF 16949 garantiza que su fábrica pueda producir productos excelentes. MLCC automotrices, condensadores de tantalio, y supercondensadores en todo momento, mientras que AEC-Q se asegura de que esos componentes puedan funcionar de manera confiable en vehículos reales.

Objetivo principal de IATF 16949 y AEC-Q

El objetivo final de ambas normas es garantizar que los componentes automotrices sean seguros, confiables y cumplan con las expectativas del cliente.

IATF 16949 Se centra en la mejora continua de los procesos de fabricación, la prevención de defectos y la eficiencia en la cadena de suministro automotriz global.

AEC-Q garantiza que cada persona cualificada MLCC automotriz, condensador de tantalio, o supercondensador Puede funcionar de forma fiable durante toda la vida útil del vehículo, incluso en condiciones ambientales y eléctricas extremas.

Para proveedores globales de electrónica automotriz como Antorcha electrónicaEl cumplimiento de IATF 16949 y AEC-Q no es solo una certificación, es un compromiso de brindar un servicio confiable. MLCC automotrices, condensadores de tantalio, y supercondensadores que cumplen con los más altos estándares automotrices a nivel mundial.